From non-contact thermometers to smart HVAC and gas safety systems, many everyday tools rely on precise heat sensing. One quiet workhorse behind these capabilities is the thermopile. It turns tiny temperature differences into useful electrical signals, opening the door to accurate measurements and small-scale energy harvesting. Here is a clear, practical guide to what thermopiles are, how they work, and why they matter.

What Is a Thermopile and How Does It Work?

The science in plain language

A thermopile is a cluster of thermocouples wired together to produce a stronger signal than a single pair could provide. Each thermocouple is made from two different conductors joined at two junctions. When the two junctions sit at different temperatures, a voltage appears. This phenomenon, called the Seebeck effect, was described in the 1800s and still underpins modern thermal sensing.

By connecting many thermocouples in series or parallel, a thermopile amplifies that tiny voltage. The device does not need an external power source to create its signal. Give it a warm side and a cool side, and it responds with a measurable output. That makes thermopiles useful in infrared thermometers, flame sensing, and other places where contact measurement is impractical or where steady, low-power operation is needed.

Turning heat into electricity

Performance depends on three big levers: materials, temperature difference, and geometry. Materials with a high Seebeck coefficient, such as bismuth telluride–based semiconductors, raise the voltage for a given temperature gap. A larger temperature difference increases output as well. Layout matters too, since good designs help keep one side warm while the other stays cool so the gradient does not collapse.

Because thermopiles produce energy from ambient heat differences, they can support tiny harvesters that power sensors in remote spots. Think of a device mounted on a warm pipe wall that sips energy from the temperature difference between the pipe and the surrounding air.

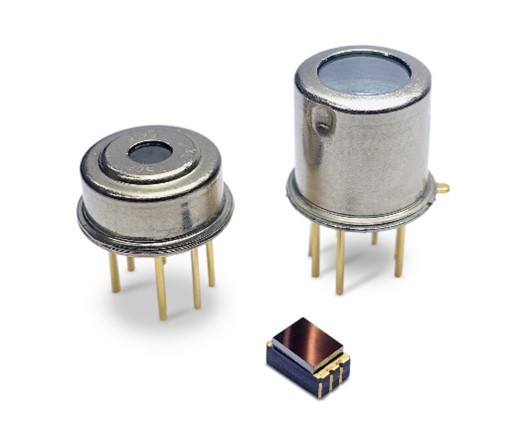

What is inside a thermopile

At the heart are matched legs of n-type and p-type thermoelectric material mounted on a stable substrate such as ceramic. Thin metal traces connect the legs into long chains. Designers often add windows, filters, or micro-optics so incoming infrared radiation lands exactly where it should, raising the temperature on the sensing junctions while the reference junctions remain cooler. The end result is a compact chip that converts heat patterns into voltage with surprising sensitivity.

Where Thermopiles Show Up

Sensors and safety systems

Non-contact temperature tools depend on thermopiles. Point an infrared thermometer at a surface, and its internal thermopile reads the infrared energy, then electronics convert that reading to a temperature. Similar sensing elements sit inside fever scanners, industrial spot pyrometers, and many thermal cameras.

Thermopiles also help keep buildings safe. In gas appliances and boilers, they verify flame presence. In gas monitoring equipment, they read changes in infrared absorption to detect specific gases. In vehicles and aerospace hardware, they assist with heat-signature tracking and feedback control.

Everyday home uses

Thermostats that read room temperature without a slow bimetal strip, ovens that regulate burner output, and smart vents that respond to heat patterns often rely on thermopile sensors. Carbon monoxide instruments can use infrared absorption with a thermopile to recognize the gas without consumable reagents. In smart homes, steady thermal feedback helps systems hold comfort targets while avoiding waste.

Industrial roles

Factories lean on non-contact temperature checks to keep lines running and quality consistent. Food processing, glass forming, and electronics assembly all benefit from reading heat without touching the product. Another growing area is waste heat harvesting. Thermopile modules can capture a sliver of energy from hot machinery housings or exhaust paths, then feed small electronics such as condition monitors.

What Is Changing in Thermopile Technology

New materials and better layouts

Researchers are testing nanostructured alloys and composites that raise Seebeck performance, resist heat flow where you do not want it, and tolerate mechanical stress. Graphene and other advanced films show promise when paired with careful layering. The aim is simple: more signal for the same temperature gap, smaller packages, and longer service life under tough conditions.

Smarter sensors

Thermopiles pair naturally with low-power radios and microcontrollers. That makes them well suited for IoT nodes that report temperatures, detect flames, or watch for leaks. Wireless units can stream data to dashboards for maintenance teams, trigger alerts when limits are crossed, and help models forecast failures before they happen.

Connected systems

Once a thermopile’s output reaches the cloud, it becomes part of a larger picture. Facilities teams can compare zones, find hotspots, and adjust setpoints. Energy managers can spot waste by correlating temperature profiles with runtime and occupancy. Over time, these data sets guide better choices about insulation, process timing, and equipment settings.

Challenges and What Comes Next

Balancing performance and price

High-output devices often use pricier materials and tight manufacturing tolerances. That can limit use in cost-sensitive products or very large deployments. Work continues on lower-cost fabrication and smarter packaging so buyers do not have to choose between signal strength and budget. Designers also pay attention to response time and resolution, since some jobs need fast readings while others favor stability.

Cleaner manufacturing

Any electronic component raises questions about sourcing and end-of-life. Producers are looking at recycled content, solvent-light processes, and designs that simplify disassembly. There is active interest in thermoelectric blends that lower environmental impact without sacrificing performance.

The road ahead

Expect tighter integration with micro-optics, better thermal isolation on chip, and data features that make field calibration easier. Hybrid devices that combine thermopile sensing with other modalities, such as humidity or pressure, are likely to grow as building and factory systems seek broader context from a single node.

Thermopiles may be small, yet their influence is wide. By quietly converting heat into useful signals and small amounts of power, they help modern systems sense, decide, and act with confidence.